Behind the Scenes: The Art and Science of Cobalt Boat Design

For over 50 years, Cobalt Boats has been a leader in luxury marine craftsmanship. But what does it really take to bring a Cobalt model to life? We sat down with Tim Kaiser, Cobalt’s Design Manager, to explore the process behind each design, from concept to launch.

It All Starts with Listening

“Listening is the first step in designing a new model,” Tim says. “We listen to our customers and our dealers. We listen to what they like, love, and hate about boating.”

This customer-first approach defines the design process at Cobalt. Every new model starts not with sketches or CAD drawings but with real conversations. The design team gathers insights from customers, dealers, quality assurance, sales, service, and marketing. These inputs shape everything from the boat’s electronics to color options and seating layouts.

At this point, the team rarely knows what the boat will look like. Styling only begins after the size and required features have been defined.

From Digital Concepts to Physical Prototypes

The design process that comes next has undergone a dramatic transformation over the past decade. Ten years ago, Cobalt’s team was just beginning to use 3D CAD software, with decks, hulls, and dashboards still being sculpted by hand. Today, however, the entire boat exists digitally before the first piece of fiberglass is laid.

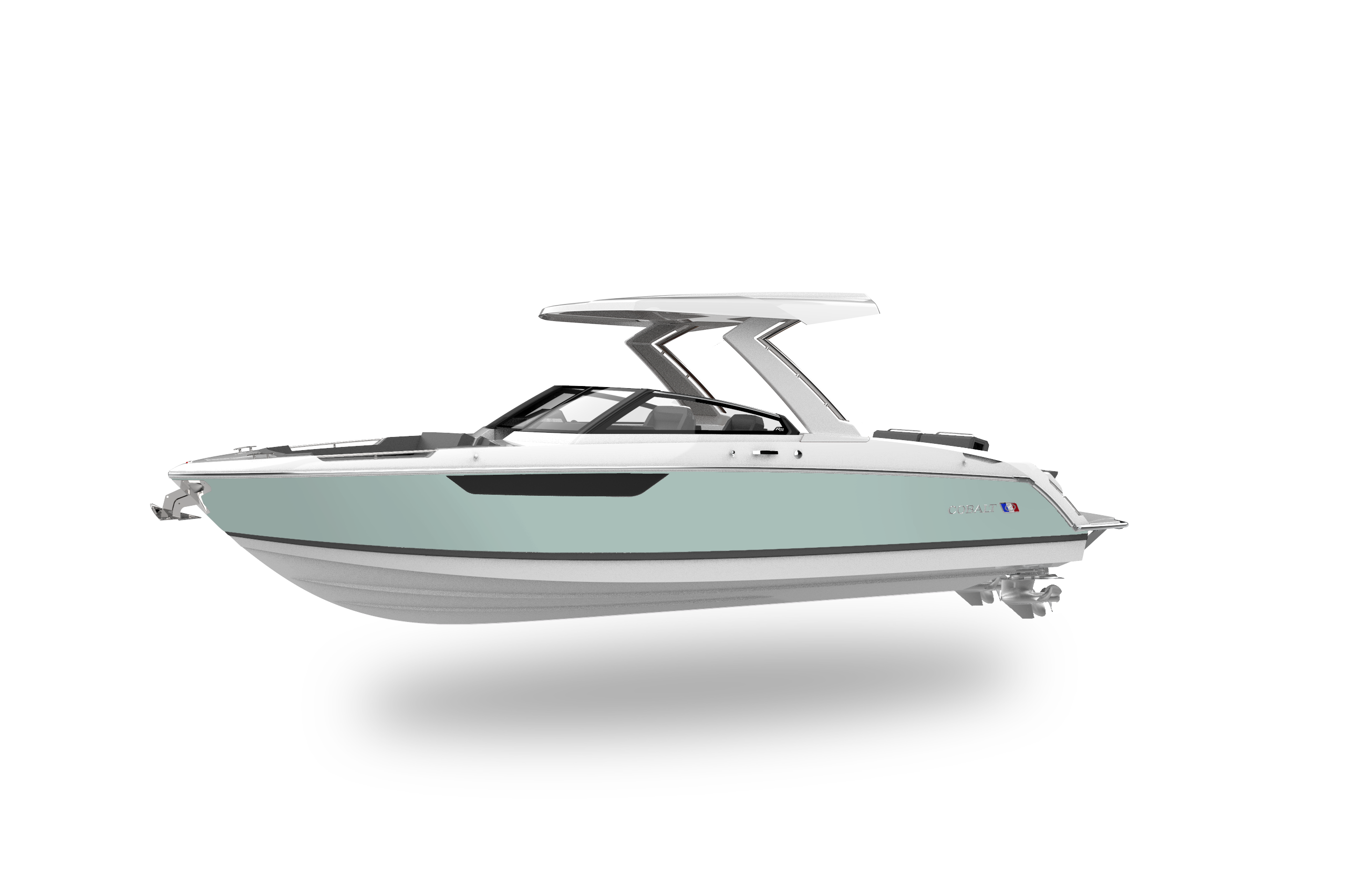

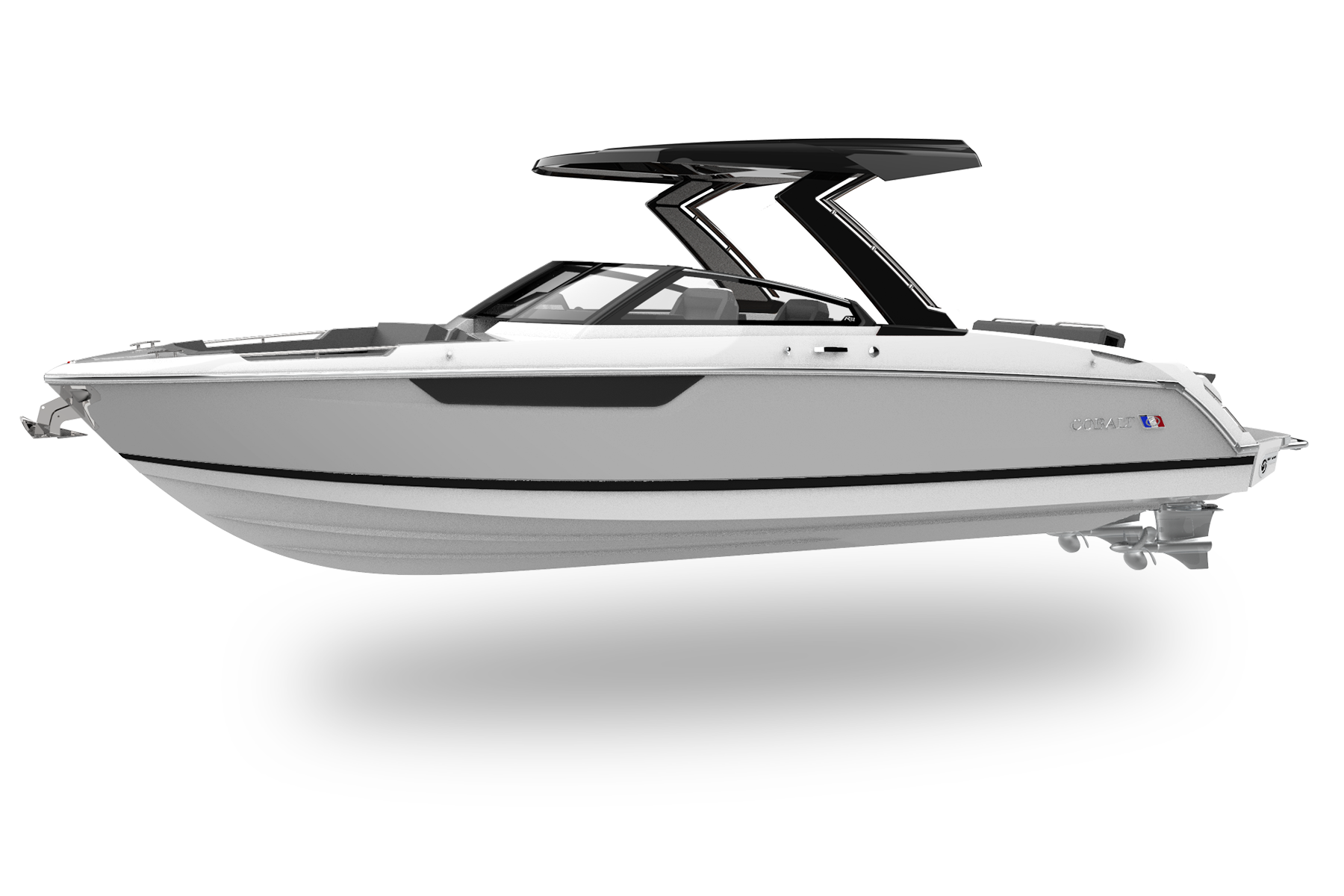

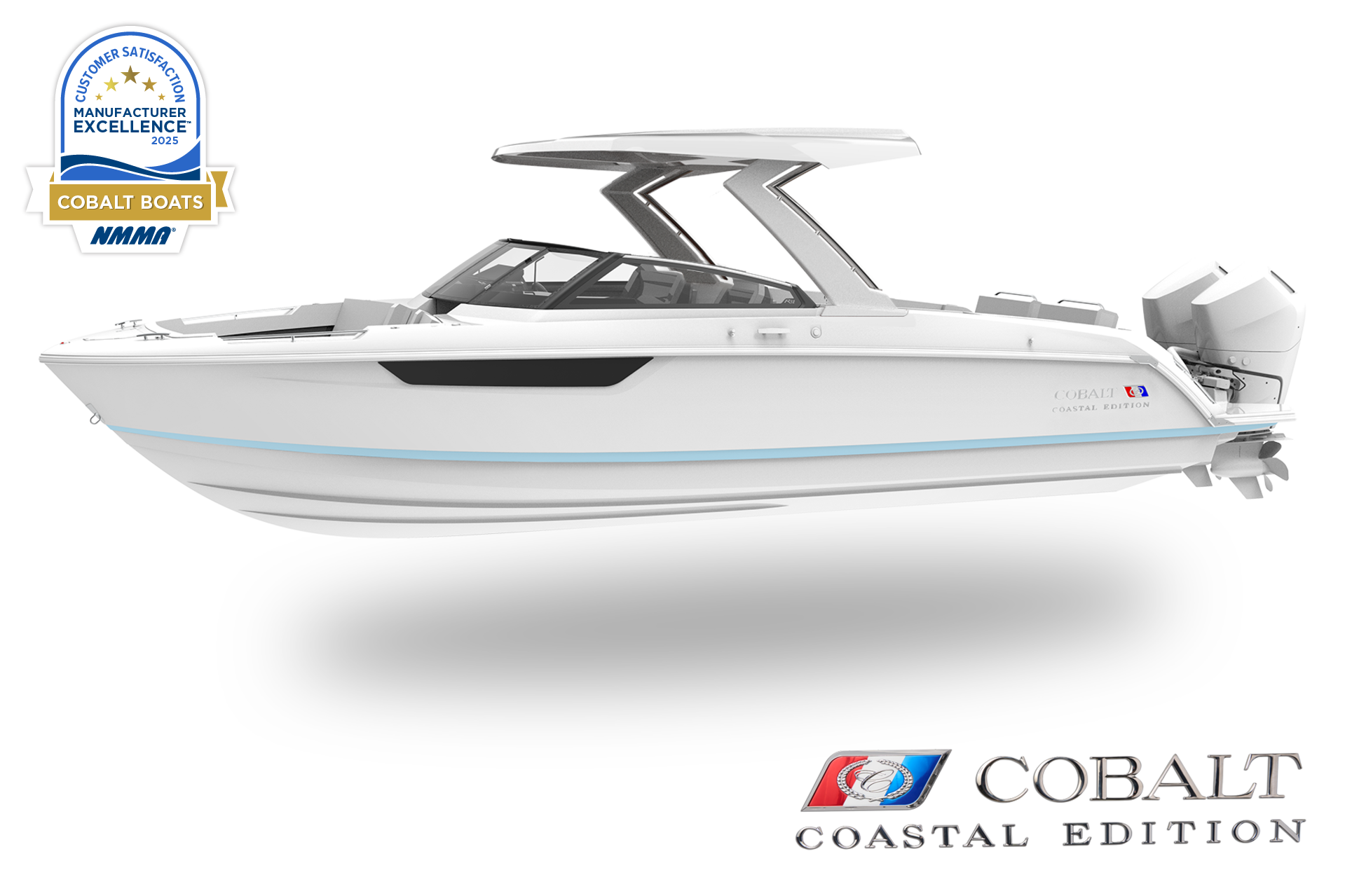

“Today the entire boat is built using 3D CAD. Everything from the bow light to the prop is included in the CAD model,” Tim explained. Designers can then apply textures and colors to cushions, flooring, and towers, creating photorealistic renders of the finished product.

But Cobalt has not abandoned the hands-on approach entirely. After the boat’s digital version is finalized, the team still creates physical mockups using cardboard and plywood to test ergonomics and spatial relationships.

Thanks to years of experience building boats, Cobalt has developed a comprehensive library of ergonomic design standards. This detailed guide includes standards for every element on the boat, ranging from seat heights and cushion thicknesses to seat back angles in different areas. All of this is considered in both the CAD model and the physical prototype.

“The value of the prototyping phase is immense,” Tim noted. “Though we have done this for 50 or 60 years now, they go through that R and D stage on every boat. We might end up moving something on the prototype half an inch and find that it makes all the difference.”

As a bonus, this digital-first approach also generates highly accurate bills of materials, enabling sales and marketing teams to strategize earlier and launch products faster than ever before

The Head: A Design Challenge and Differentiator

One of the most complex design challenges facing Cobalt’s team involves the head compartments, which have become a key differentiator for our boats. While large cruisers and yachts often offer ample space for hotel-quality marine facilities, fitting functional heads into smaller boats like 26-foot models requires advanced engineering and smart design.

“When you start to scale that down into a much smaller boat, it is an extremely difficult process,” Tim explained. The challenge lies in fitting sinks, toilets, and plumbing into tight spaces while maintaining comfort, usability, and functionality within the head compartment.

For boats where a traditional head is impractical, Cobalt offers innovative alternatives such as modular systems that can convert the space into storage areas, cooler compartments, or equipment racks.

This flexibility reflects Cobalt’s understanding of diverse customer needs. Some owners prioritize a private changing space or bathroom, while others prefer maximizing storage for gear, water toys, and equipment.

Innovation Flows Both Ways

Contrary to the typical industry approach, where premium features are introduced on flagship models and slowly make their way into smaller boats, Cobalt’s innovation flows in both directions. The hydraulic swim platform, first introduced on the compact A25 model fifteen to sixteen years ago, has now been scaled up and integrated into models all the way up to 35 feet.

Similarly, the popular Splash and Stow inflatable mat system began on the A29 and has evolved into larger formats with added features like rock climbing walls and inflatable islands.

“Every time a boat comes out with anything that is received very well by the customer base or puts us at an advantage, we try to incorporate that into another model, scaled up or down as needed,” Tim explained.

Innovation at Cobalt is not always visible to the customer. Behind the scenes, manufacturing improvements can lead to reduced costs, allowing more premium features to be included at the same price or enabling more competitive pricing overall.

The Cobalt Difference: No Compromise

What sets Cobalt apart in a competitive market is not exclusive access to better materials or technology. As Tim pointed out, “All boat builders have the same access to raw materials, electronics, and technology as Cobalt.” The true differentiator, he emphasized, lies in the company’s philosophy. “What sets us apart is our understanding that compromise is not acceptable. We choose not to compromise on materials or product design strictly due to cost or ease of manufacturing.”

This uncompromising approach brings its own challenges. Cobalt customers expect it all, and rightly so. They demand luxury, high performance, the latest marine technology, and consistent quality and reliability.

Meeting those expectations means sourcing luxury fabrics and marine-grade vinyls that hold up in extreme conditions. It means engineering hulls that maintain efficiency and performance in a variety of water conditions. It also means integrating advanced marine electronics that can withstand constant exposure to water, vibration, and sun.

The Manufacturing Reality Check

With the design finalized, the process moves to manufacturing. But what many may not realize is that production planning starts months before the CAD drawings are complete.

The manufacturing process involves close coordination between multiple teams at the plant. Manufacturing directors and supervisors join early meetings to review the new model and begin outlining the steps required to bring it to life.

At the same time, teams are identifying what tools, facility improvements, or process changes the production line may require for the new model.

“Sometimes during this process, a napkin sketch can turn into a million-dollar facility,” Tim noted with a laugh.

These Design for Manufacturing discussions run in parallel with the creative process. They require designers to understand real-world production constraints and ask manufacturing teams to make space for new innovations.

Designing and producing a new Cobalt model is an intricate collaboration involving dozens of disciplines and hundreds of decisions. Every element must align to ensure a smooth launch.

“There is never a perfect project until it is finished,” Tim reflected.

After months of planning, refinement, and boardroom discussions among Cobalt’s design, engineering, and manufacturing teams, the final product rolls off the line. And that is what matters most.

“When that customer comes onboard and starts that boat, he has no clue about the hundreds of people who came together to solve all kinds of complex engineering challenges to make that boat happen. He just knows he got a Cobalt that meets his expectations,” said Tim.

Looking to the Future

As we look ahead, Cobalt’s focus remains on delivering the luxury and performance our customers expect, while continuing to embrace new technologies and evolving materials.

Vinyl suppliers now offer darker color options that stay cool in direct sunlight. Fiberglass laminates are becoming stronger and lighter. Engines and drives are more efficient, more reliable, and easier to use than ever before.

Through it all, the Cobalt team stays focused on a single mission: to uphold our promise to customers by building boats that look and feel exceptional both on the water and at the helm.

From that initial listening session to the moment a customer takes delivery, every Cobalt boat reflects hundreds of decisions, hours of refinement, and a deep commitment to excellence. It is this attention to the entire process, not just the final product, that has kept Cobalt at the forefront of luxury boating for over 50 years.

So, the next time you see a Cobalt cutting across the water, remember that it began not with a sketch, but with someone listening closely to what boaters really wanted, then refusing to compromise in bringing that vision to life.

A29

A29  R4

R4  R6

R6  R8

R8  R31

R31  R33

R33  R35

R35  R35 Coupe

R35 Coupe  CS22

CS22  CS23

CS23  CS23 Surf

CS23 Surf  R4 SURF

R4 SURF  R6 SURF

R6 SURF  R8 Surf

R8 Surf  R31 Surf

R31 Surf  R33 Surf

R33 Surf  R35 Surf

R35 Surf  R4 Coastal

R4 Coastal  R6 Coastal

R6 Coastal  R8 Coastal

R8 Coastal  R31 Coastal

R31 Coastal  R33 Coastal

R33 Coastal  R35 Coastal

R35 Coastal  R35 Coastal Coupe

R35 Coastal Coupe